Performance — The Lifeblood of Process Management

The purpose of process is performance.

This should be the mantra of every process practitioner. If we aren't relentlessly focused on process, and therefore organizational performance, then we are, by our own definitions, just creating waste.

Process-based management is about consistently delivering mindfully targeted levels of organizational performance. The models, tools, and methods are important, but only if they advance this vital purpose.

In this column I explore key approaches that keep process performance in sharp focus.

Process performance management

The basic unit of performance is the Process KPI (PKPI). Without a properly designed PKPI we can only guess about performance and have no way of knowing about improvement.

PKPIs are a bespoke design for each process, not just a best-fit match to an existing list of functional KPIs. Forget any existing KPIs. Start with the process and ask what is it meant to deliver, and to whom, and how would you know if that is happening. Pick the vital few PKPIs and targets. If you could only measure three things, what would they be? What if just one?

OK, we have a PKPI and related target. Let's zoom out and look at the big picture.

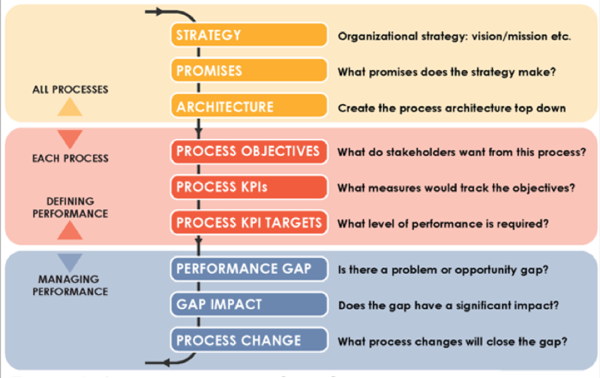

Figure 1. Activating process-based management

In my last column I discussed how we create a measurement and management system.

Figure 1 is an overview of how the PKPIs fit into a system of continuous measurement.

There is also a short video on this topic.

Finding the gap

At the heart of active process-management is the constant search for performance gaps, the closure of which is the only path that leads to performance improvement.

A performance gap might be an opportunity (to do something different) or a problem gap, and the problem might be existing or emergent. Without at least one of those there can be no improvement. And to find them we must be actively looking — for those who wait in hope, good things will go whizzing by unseen.

Having found a gap, we must then ask if we care enough to fix or avoid the problem or realize the opportunity. Is the gap serious enough to close? Now? Later? We have limited resources to apply to process analysis and improvement. Which performance gap will likely give the best return for that effort and cost?

Process performance improvement requires focus. Focus on the right process, focus on the right PKPI and target(s), focus on the right performance gap, focus on the right solution, and focus on the right time.

Which process?

But which process? There are hundreds, even thousands, of them depending on how deep we are in the process hierarchy. It's not possible to measure them all, and the good news is we don't need to.

Firstly, we need a way to find 'all' of our processes by documenting them from the top down, starting with organizational strategy. This is an enterprise process architecture (EPA), and I discussed that in detail in this column and this video.

An EPA is the primary artifact in process-based management. It shows how value is created, accumulated, and delivered, i.e., how strategy is executed.

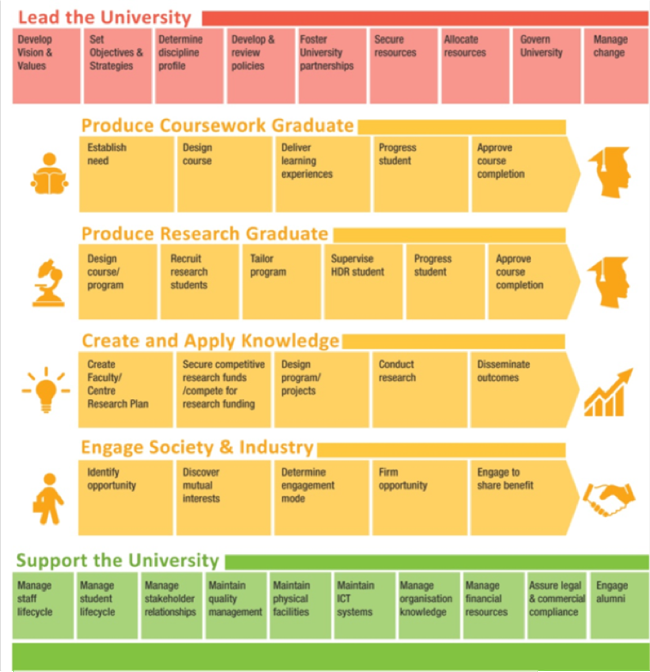

Figure 2. A university example EPA

More than just a picture, an EPA provides a unifying canvas for all process analysis, management, and improvement work. Starting with the EPA, we can make informed decisions about which processes should be actively managed.

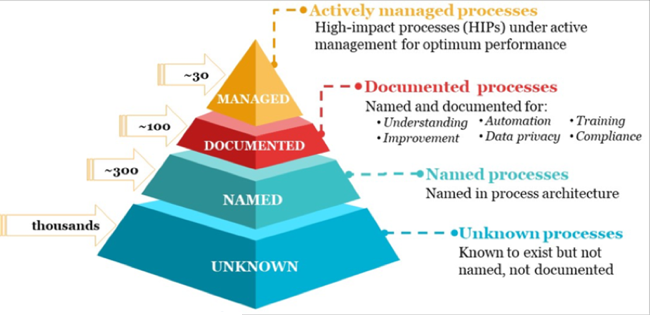

The EPA gives strategic shape to our processes, and puts them in context, but there are still just as many of them. enter the Process Priority Pyramid. See my earlier column and this video for a more detailed treatment.

It's useful to think of our processes as a pyramid with the critical few at the top and the important many further down the structure. Those processes at the apex of the pyramid are the high-impact processes (HIPs). Developing a shared understanding about which are our HIPs is an important milestone in developing process-based management.

Figure 3. Process Priority Pyramid

The 'continuous' bit

everyone likes the idea of continuous improvement. What's not to like — everything getting better all the time. In practice it often has two problems: it's not really continuous, and it's hard to see the improvement.

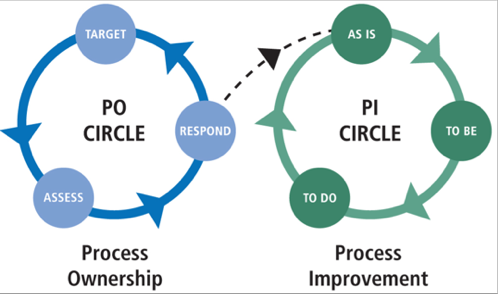

Figure 4. The Tregear Circles

Let's get the circles turning. Brief explanation of Figure 4 here and — yes, you guessed it — there is a previous column and a video.

The PO circle is continually testing process performance to uncover actual or emergent problem gaps driven by measurement, and opportunities driven by ideas.

The repeating cycle of target—assess—respond is the insistent drumbeat of effective process-based management.

The PI circle is the process-improvement cycle that identifies the current state, defines the future state, and then makes evidence-based changes required to close prioritized performance gaps. The PI circle can be instantiated with any formal or informal process improvement methodology.

The PO circle determines whether change is required in response to a current or emergent performance anomaly, or a development opportunity. The PI circle discovers, details, and delivers the business-process change. The PO circle also tests if changes were effective.

Many organizations do something like continuous process improvement; not enough do continuous process management. Turning the circles makes that possible.

Signals in the noise

Performance varies. Measurement involves variation.

A lot of variation is just a routine part of the operation of a system — or process. The performance of a process is not going to be constant. It will vary, and that's the point of measurement. We wouldn't need to measure a constant.

While a lot of variation is routine, some variations are exceptional. They signal that something has happened, something that is worth investigating.

The routine variation we find in any measurement dataset for a process is not worth investigating. It has no assignable cause, and it would be a waste of time trying to find one.

So, we want to find signals in the noise that tell us that a significant change in performance has occurred. That change might be an improvement or a degradation in performance. It might have been expected or a surprise.

Our analysis efficiency and effectiveness are greatly improved if we chase the signals and ignore the noise.

How do we do that? Using only the performance data, a Process Behavior Chart (PBC) provides a tight focus on those signals.

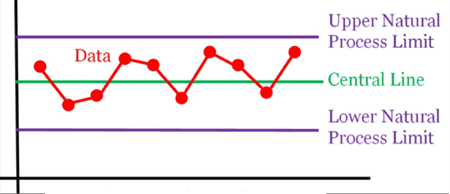

Figure 5. Process Behavior Chart

Simple calculations allow us to create a PBC as shown in Figure 5. This defines the upper and lower limits of routine variation of process performance, and we apply simple rules to detect signals of exceptional variation. Unless there is a change to the process, which may be intentional or unintentional, we can assume with high certainty that process performance will vary between these limits. Relax. Wait for a signal before searching for a cause.

Where could we find out more? Oh, wait … there's a column and a video.

The linchpin

The Process Owner (PO) is the linchpin of effective process-based management. Since the organization chart says nothing of practical value about who manages across the chart, we need a new role. More about Process Owners here and here. And here.

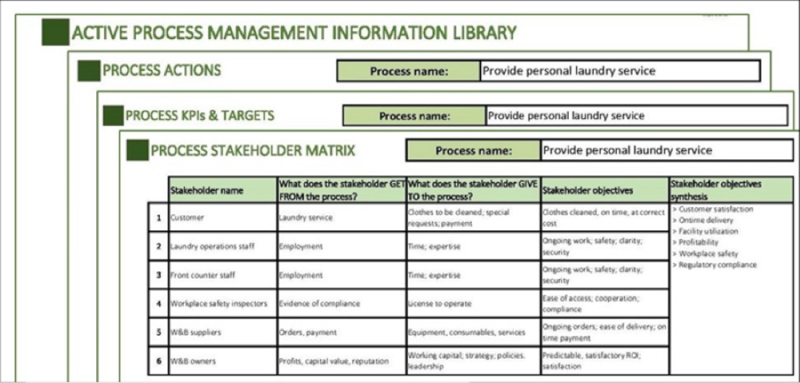

To track performance and develop a deep understanding of their process, a PO must maintain a body of information. I call this the Process Management Record (PMR) and it is illustrated in Figure 6.

Figure 6. Process Management Record

Being a PO is not a solo activity. The main activity is facilitating analysis and review by a process stakeholder group, which is mainly comprised of the functional managers directly involved in the functional parts of the cross-functional process. The PMR is the embodiment of that collaboration.

Need more detail? Of course, there's a video.

Delivering process performance

The search for process performance mastery should animate the lifecycle of our process work. Which process? Who cares? What would good look like? How would we know? What has happened so far? Is the process stable within acceptable limits? What could be possible? What will happen next? What risks? What opportunities?

Our ultimate goal must be to deliver proven, valued, business benefits, i.e., benefits for the business, valued by the business, and proven with data about which there is no dispute.

Performance gives purpose to, and is the thread that ties together, all our process management and improvement work. Or at least it should be.

[And one last time — yes, there is a column and a video!]

# # #

About our Contributor:

Online Interactive Training Series

In response to a great many requests, Business Rule Solutions now offers at-a-distance learning options. No travel, no backlogs, no hassles. Same great instructors, but with schedules, content and pricing designed to meet the special needs of busy professionals.

How to Define Business Terms in Plain English: A Primer

How to Use DecisionSpeak™ and Question Charts (Q-Charts™)

Decision Tables - A Primer: How to Use TableSpeak™

Tabulation of Lists in RuleSpeak®: A Primer - Using "The Following" Clause

Business Agility Manifesto

Business Rules Manifesto

Business Motivation Model

Decision Vocabulary

[Download]

[Download]

Semantics of Business Vocabulary and Business Rules